Variable-Speed Direct-Drive Screw Chiller

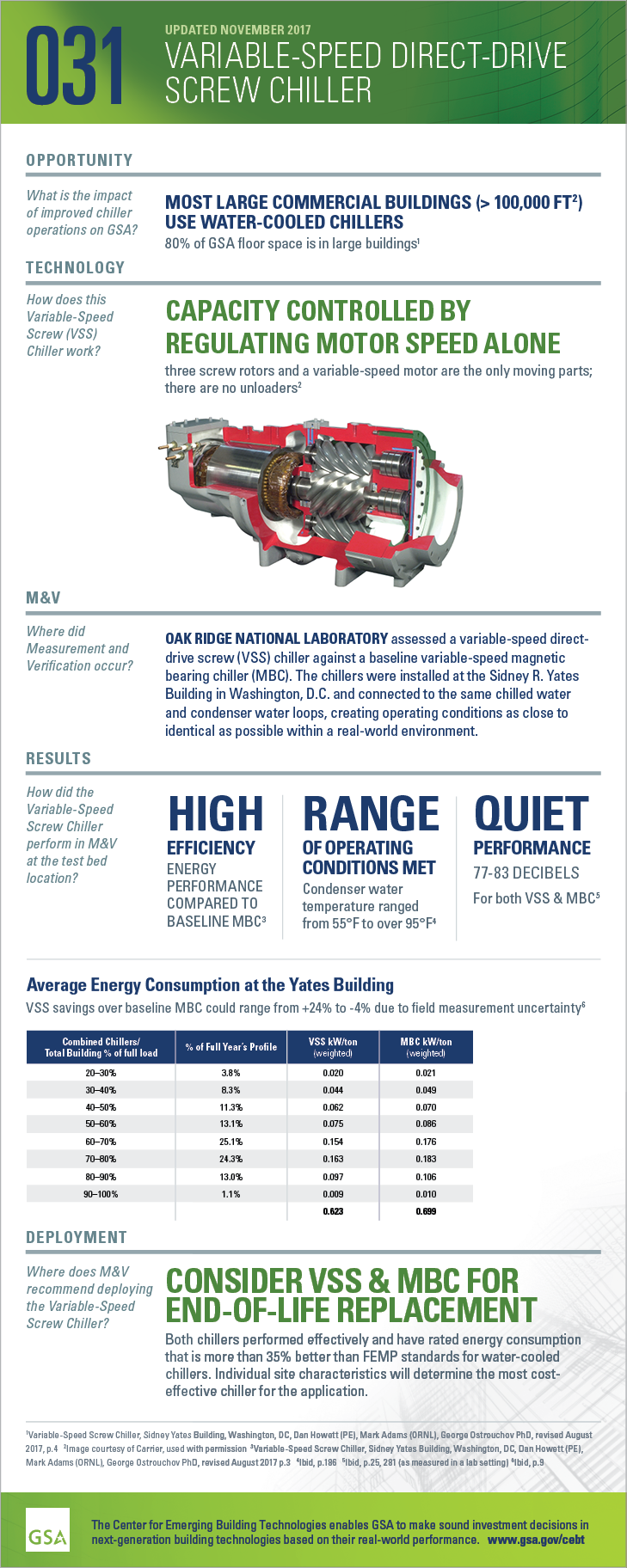

Green Proving Ground (GPG) evaluated a variable-speed direct-drive screw (VSS) chiller against a baseline state-of-the-art chiller technology, the variable-speed magnetic bearing chiller (MBC). Results showed similar performance for both chillers.

Agencies should consider both VSS and MBC for new or end-of-life chiller replacements. Individual site characteristics will determine the most cost-effective chiller technology for a particular application. View full-size infographic. [PDF - 455 KB]

Reference above to any specific commercial product, process or service does not constitute or imply its endorsement, recommendation or favoring by the United States Government or any agency thereof.

WEBINAR

NEWSLETTER

ADDITIONAL RESOURCES

Last updated: Jun 28, 2023

Top

U.S. General Services Administration

U.S. General Services Administration