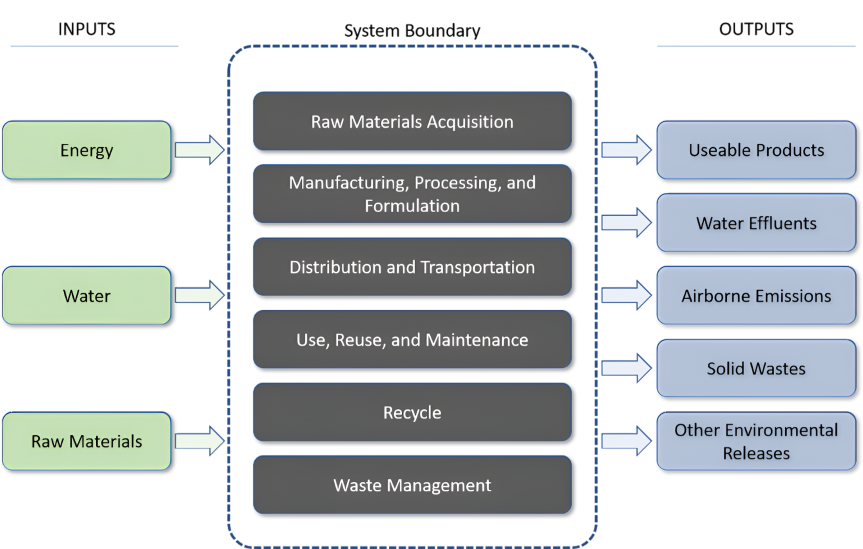

Life Cycle Assessment aims to quantify the environmental impacts that arise from material inputs and outputs, such as energy use or air emissions, over a product’s entire life cycle to assist consumers in making decisions that will benefit the environment. LCA is typically a “cradle-to-grave” approach, which begins with the gathering of raw materials from the earth to create the product and ends at the point when all materials are returned to the earth.

It is important to take into consideration the entire life cycle of materials, systems, and the whole building when making design or purchasing decisions.

Benefits of LCA

Provide comprehensive view of the environmental impacts and reduce impact and costs

Quantify environmental effects such as overall energy consumption or air emissions

Allow comparison of alternatives “apples to apples” and see more than just the “use” phase

Recognize inefficiencies or significant changes across life cycle phases

Challenges with LCA

Here are some questions that the environmental experts, designers, engineers, regulators, and companies can ask when trying to overcome LCA challenges.

| Defining LCA boundaries and scope | Where do I want to draw the line? What attributes am I interested in comparing against one another? How far down the chain do I want to identify and quantify these material flows, and is that data even available? |

|---|

| Data availability | Is data available to quantify material inputs and outputs at all stages of my defined scope? Is this data from a reliable source (e.g., manufacturer)? |

|---|

| Quantifying environmental impacts | How can these material flows be quantified into environmental categories (e.g., global warming)? |

|---|

| Weighting impacts across stakeholders | What environmental category are we most concerned about (e.g., global warming, energy use, acidification) and how does it compare to other environmental attributes? |

|---|

Life cycle assessment example

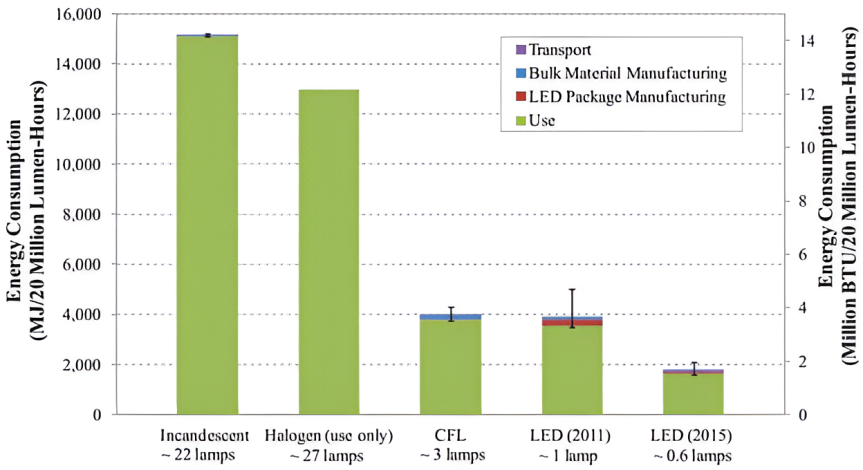

The US Department of Energy has developed an LCA report [PDF] to help evaluate the energy and environmental benefits of LEDs when compared to incandescent and fluorescent lighting. When using LCA to compare equipment, it is important to establish a common unit of performance by which each will be judged. For lighting, the useful life of the three alternatives below varies greatly. When comparing lighting options, it is important to consider the labor and disposal impacts of bulb replacements.

Figure 1: Number of Lamps Needed to Supply 20 Million Lumen-Hours.1

The figure below sums up the results of DOE’s study: though the manufacturing of LEDs may have a greater environmental impact than its competition, the dominant source of impact is the lifetime energy use. In 2011, LEDs were roughly equivalent to CFLs with respect to LCA. According to an updated LCA study conducted for the Illuminating Engineering Society in 2018, new A19 LED lamps “all perform better than the 2011 A19 LED on environmental impacts and all are now significantly better than traditional lighting technologies”.3

Figure 2: Life-Cycle Energy of Incandescent Lamps, CFLs, and LED Lamps.2

1,2 US Department of Energy, “Life-Cycle Assessment of Energy and Environmental Impacts of LED Lighting Products,” February 2012 [PDF]

3 Illuminating Engineering Society, “Environmental and Energy Improvements of LED Lamps over Time: A Comparative Life Cycle Assessment”, October 2018

U.S. General Services Administration

U.S. General Services Administration